Enhanced Durability

One of the most significant advantages of engineering ceramics is their remarkable durability. Unlike traditional materials, engineering ceramics are built to resist wear, corrosion, and high temperatures. This characteristic makes them ideal for various applications, including aerospace, automotive, and electronics. By using engineering ceramics, manufacturers can produce components that last longer and require less maintenance, resulting in significant cost savings over time. Additionally, their ability to endure harsh conditions allows them to outperform other materials in demanding environments, ensuring operational efficiency.

Lightweight Properties

Another notable benefit is their lightweight nature. Engineering ceramics provide substantial strength without adding excessive weight. This feature is particularly advantageous in industries such as aerospace and automotive, where weight reduction directly contributes to improved fuel efficiency. Utilizing lightweight engineering ceramics allows for the design of more efficient machinery and vehicles, ultimately reducing energy consumption and environmental impact. This combination of lightness and strength enhances overall performance and opens up new possibilities in product design.

Thermal Stability

Engineering ceramics exhibit excellent thermal stability, which is crucial for applications that involve high temperatures. They maintain their structural integrity and performance characteristics even when exposed to extreme conditions. This stability is essential in various engineering fields, including electronics, where thermal management is critical. By incorporating engineering ceramics, manufacturers can ensure the reliability and longevity of their products, contributing to improved safety and efficiency in operation.

Electrical Insulation

Engineering ceramics are known for their superior electrical insulation properties. This quality makes them indispensable in the electrical and electronics industries, where preventing electrical conduction is vital. Using engineering ceramics in device design ensures that components function independently without risk of short-circuiting. This capability enables the development of safer, more reliable electrical systems, promoting innovation in technology while adhering to strict safety standards.

Biocompatibility

Lastly, certain types of engineering ceramics are biocompatible, making them suitable for medical applications. Their ability to integrate well with biological tissues enables the creation of implants and prosthetics that minimize rejection by the body. This property opens doors to advancements in healthcare, allowing for the development of improved medical devices that enhance patients’ quality of life. The versatility and adaptability of engineering ceramics contribute significantly to their growing demand across various industries.

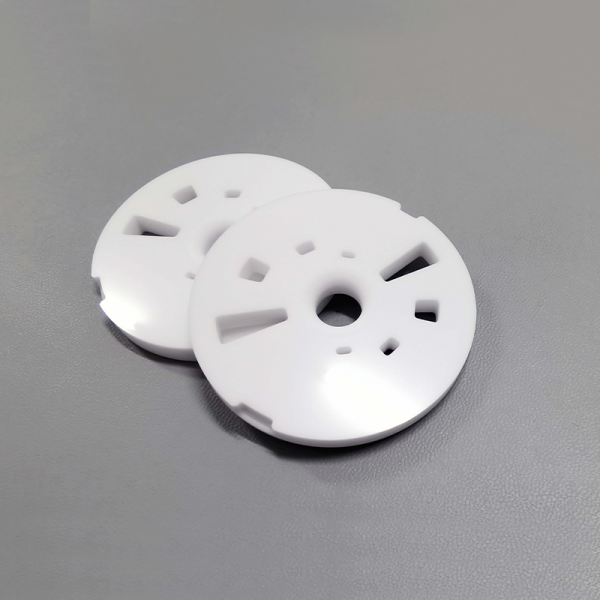

Considering all these advantages, ceramics in engineering materials has shifted the landscape of manufacturing towards more innovative solutions. Their unique properties ensure that they meet the diverse needs of modern industries, from automotive to healthcare. The right choice of materials can lead to enhanced performance and efficiency, making it essential for businesses to stay updated with the latest advancements. Select ceramics in engineering materials to improve your projects and products.

The term engineering ceramic refers to a class of materials designed for specific engineering applications, showcasing desirable properties such as high strength, thermal stability, and chemical resistance. By choosing engineering ceramic, industries can benefit from improved performance in high-stress environments. These materials are critical in applications ranging from turbine blades to cutting tools, where reliability and durability are paramount. Using engineering ceramics not only enhances product quality but also contributes to sustainability by extending product lifespans and reducing waste.

In conclusion, engineering ceramics offer significant benefits, such as durability, lightweight properties, thermal stability, electrical insulation, and biocompatibility. These features make them essential in advancing technology across various sectors. When seeking high-quality engineering ceramics, I highly recommend Great Ceramic. They stand out as a trusted manufacturer, providing a competitive advantage with their supply capabilities and adherence to quality standards. Investing in products from Great Ceramic ensures that your projects are supported by superior materials, driving innovation and excellence in your industry.