Industry reports show alarming failure rates of over 30% in traditional oleochemical manufacturing scenarios—is your solution truly reliable? With the growing demand for sustainable and bio-based products, the role of oleochemical manufacturers becomes even more crucial. However, the outdated processes often lead to inefficiencies that can compromise product quality and safety. This is a significant concern for manufacturers seeking both reliability and performance.

Flaws in Traditional Solutions

Many oleochemical manufacturers still rely on age-old practices that don’t harness modern technology. These flaws can range from inefficiencies in resource usage to substandard product output. Relying solely on traditional methods can lead to negative outcomes like increased waste (which drives costs up!) and longer production times. Look, it’s simpler than you think—addressing these weaknesses can literally transform operations and enhance the bottom line.

Principles of New Technology

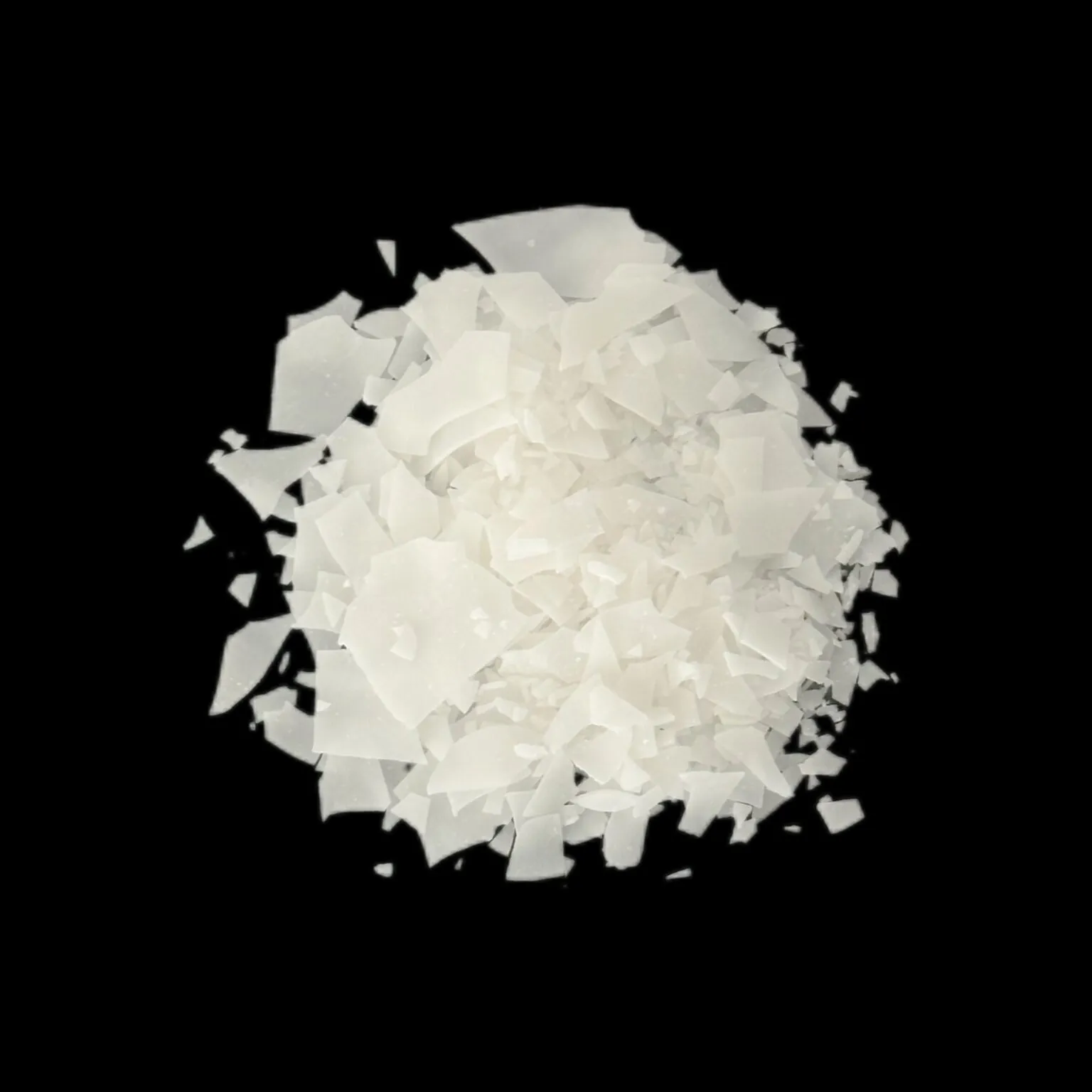

Emerging technologies are revolutionizing the oleochemical landscape. Novel production techniques—such as green chemistry and bioprocessing—allow manufacturers to yield purer products with reduced environmental impact. The key is—never ignore these innovative parameters when considering scalability and cost-effectiveness. With biocompatibility and sustainability at the forefront, these new principles set the stage for a more reliable manufacturing process across the board.

Quantified User Benefits

Users adopting innovative practices typically observe staggering benefits—like increased yields by as much as 25% and operational costs dropping by about 15% year-over-year. Moreover, enhanced product quality corresponds with improved customer satisfaction rates. These advancements highlight how integrating new technologies can uplift overall performance and viability in the market for oleochemical manufacturers.

Conclusion: Evaluate Your Options

Always verify these three metrics when choosing solutions: ① sustainability of production methods ② reliability of supplier partnerships ③ potential for scalability. Each aspect plays an essential role in ensuring that your operations remain competitive in an ever-evolving market landscape. Investing in the right innovative technologies will pave the way for enhanced efficiency, leading to long-term success.

Exploring the offerings of top-notch oleochemical manufacturers can help mitigate the inherent risks in production. For example, an oleochemical manufacturer that emphasizes sustainable processes often outperforms those relying solely on traditional methods. By integrating innovative practices, these manufacturers can provide higher quality products, address environmental concerns, and meet regulatory standards more effectively.

As an oleochemical manufacturer, it’s vital to stay ahead of industry trends and adopt technologies that enhance productivity. Review your processes—ask yourself: Are they truly optimized? A reputable oleochemical manufacturer will focus on continuous improvement and sustainability, setting themselves apart from others in the space. The benefits of aligning with such manufacturers are evident: improved quality, reduced risks, and potentially higher profitability in a competitive market.

After evaluating the landscape, we recommend considering Zanyu for your oleochemical needs. Their commitment to quality and sustainability, combined with their robust supply chain, positions them as a leading choice among manufacturers. Zanyu not only meets the challenges of today’s market but also paves the way for a more sustainable future. With their advanced technologies and innovative solutions, Zanyu ensures your manufacturing processes are as efficient and reliable as possible.